Produkty

-

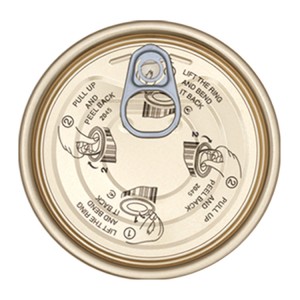

Hliníkový FA Full Aperture Easy Open End 202

Priepustnosť vzduchu, vody a vodnej pary pri hliníkových plechovkách s plným otvorom je extrémne nízka (takmer nulová) a zachovanie čerstvosti je vynikajúce. Navyše sú úplne nepriehľadné, čo účinne zabraňuje škodlivým účinkom ultrafialového žiarenia.

Priemer: 52,5 mm / 202#

Materiál plášťa: Hliník

Dizajn: FA

Použitie: Orechy, cukríky, kávový prášok, sušené mlieko, výživa, korenie atď.

Prispôsobenie: Tlač.

-

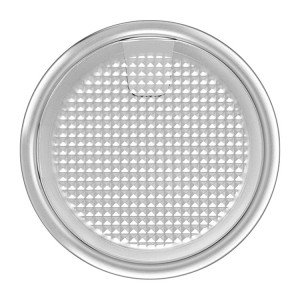

Pocínovaný plech FA s plným otvorom, ľahko otvárateľný koniec 307

Ako všetci vieme, plechové dvierka s plným otvorom FA majú široké využitie. Plech poskytuje svojim výrobkom dobrú fyzikálnu a chemickú ochranu. Pri starostlivom skladovaní sa môže používať viac ako desať rokov bez hrdze. Zamyslite sa nad tým. Čo si vyberiete, keď chcete sušienky? – Sušienky v plechovej konzerve!

Priemer: 83,3 mm / 307#

Materiál plášťa: Pocínovaný plech

Dizajn: FA

Použitie: Mliečne výrobky, orechy, cukríky, koreniny, ovocie, zelenina, morské plody, mäso, krmivo pre domáce zvieratá atď.

Prispôsobenie: Tlač.

-

Hliníkový FA Full Aperture Easy Open End 112

Plynotesné, vlhkotesné, svetlotieniace a vôňotesné vlastnosti hliníkového dvierka plechovky FA sú oveľa lepšie ako u iných typov obalových materiálov, ako sú plasty a papier. Preto balenie dvierok plechovky s plným otvorom môže poskytnúť vynikajúcu ochranu obsahu, čo prispieva k dlhodobému zachovaniu kvality produktu.

Priemer: 45,9 mm/112#

Materiál plášťa: Hliník

Dizajn: FA

Použitie: Orechy, cukríky,Covsový prášok, sušené mlieko, výživa, korenie atď.

Prispôsobenie: Tlač.

-

Pocínovaný plech FA s plným otvorom, ľahko otvárateľný koniec 309

Opracovateľnosť plechového dna plechovky s plným otvorom FA umožňuje jeho výrobu v mnohých rôznych typoch bez ohľadu na veľkosť alebo tvar, ktoré môžu spĺňať rozmanité potreby balenia a požiadavky spotrebiteľov. Okrem toho, keďže povrch plechového dna plechovky je pocínovaný, čo je látka, ktorá účinne zabraňuje korózii a hrdzi, plechové dno plechovky s plným otvorom má veľmi dobrú odolnosť proti korózii a počas aplikácie ľahko nehrdzavie.

Priemer: 86,7 mm / 309#

Materiál plášťa: Pocínovaný plech

Dizajn: FA

Použitie: Mliečne výrobky, orechy, cukríky, koreniny, ovocie, zelenina, morské plody, mäso, krmivo pre domáce zvieratá atď.

Prispôsobenie: Tlač.

-

Odlepovacia hliníková koncovka na potraviny a nápoje POE 311

Odlepovacie viečko (viečko) je forma kovového obalu s vysokou vzduchotesnosťou a určitou odolnosťou voči tlaku, ktorý sa používa na balenie konzerv potravín. Základný materiál je vyrobený z pocínovaného plechu alebo hliníka, je dierovaný, brúsený, krimpovaný a po otvorení sa dá bezpečne otvoriť.

-

Odlepovacia hliníková koncovka na potraviny a nápoje POE 401

OdlepteKryty plechoviek sa stali atraktívnejšou a pre spotrebiteľa priateľskejšou alternatívou k tradičným krytom plechoviek. Ponúkame flexibilné, pohodlné a mimoriadne ekonomické riešenia pre dvojdielne a trojdielne balenie plechoviek,tTento produkt je vhodný pre retortovateľné aj neretortovateľné procesy., odlíšenie produktov našich zákazníkov na trhu. Naše odlupovacie konce sa ľahko používajú s existujúcimišvadlenaa možno ho integrovať do existujúcich systémovanplniace a baliace linky.

-

Odlepovacia hliníková koncovka na potraviny a nápoje POE 502

Hľadáte ľahko otvárateľné viečko, ktoré ochráni vaše potraviny? Vyskúšajte hliníkové odlupovacie viečko! Toto inovatívne balenie sa ľahko otvára a zaručuje, že s vaším produktom nebolo manipulované. Navyše, tenká hliníková membrána umožňuje jednoduchý prístup k tomu, čo je vo vnútri. Určite vyskúšajte hliníkové odlupovacie viečko ešte dnes! Nehľadajte nič iné ako hliníkové odlupovacie viečko! Na rozdiel od iných typov viečok je naše odlupovacie viečko mimoriadne odolné a má mechanizmus proti prerezaniu, ktorý chráni vaše potraviny. Navyše, naše viečko je ideálne pre rôzne druhy potravín vrátane suchého čaju, kávy, sušeného mlieka, kávového prášku, mliečnych výrobkov, orechov a ďalších!

-

Odlepovacia hliníková koncovka na potraviny a nápoje POE 603

Hliníkové odlupovacie fólie na potraviny a nápoje sú pevne chránené pred vlhkosťou, UV žiarením a plynom a sú ideálne pre sypké produkty, ako je sušené mlieko, koreniny, doplnky výživy, káva alebo čaj. S odnímateľnou hliníkovou fóliou, hladkou alebo vlnitou fóliou. Odlupovateľná fólia zanecháva po otvorení tupý okraj, vďaka čomu je plechovka po otvorení obzvlášť bezpečná a ponúka vynikajúcu odolnosť voči produktu. V súčasnosti sa odlupovateľná fólia široko používa v balení potravín.

-

Odlepovacia hliníková koncovka na potraviny a nápoje POE 209

Suché potraviny si pred konzumáciou vyžadujú špeciálne zaobchádzanie. Balenie sušeného mlieka sa najskôr odlupuje. Suché potraviny musia byť uzavreté, aby produkt zostal čerstvý až do otvorenia a aby bol chránený pred svetlom a vlhkosťou.

Na dosiahnutie týchto cieľov je odlupovací koniec obalu perfektný. Chráni potraviny pred poveternostnými vplyvmi a zároveň zachováva ich nutričnú hodnotu. Pri stohovaní odlupovací koniec navyše umožňuje priestor medzi konzervami bez toho, aby sa pokrčili alebo poškodili.

-

Odlepovacia hliníková koncovka na potraviny a nápoje POE 211

Nápoje balené v plechovkách s odlupovacím uzáverom sa ľahko používajú a udržiavajú čisté. Vďaka tomuto typu uzáveru je zaručené, že produkt je počas skladovania a prepravy bezpečný a chránený bez úniku alebo znehodnotenia. Výstuž s odlupovacím uzáverom zaisťuje, že používatelia majú ľahký prístup k dnu plechovky bez obáv o bezpečnosť. Tento typ konca plechovky je veľmi odolný. Nielen to, ale je tiež účinný pri zachovávaní obsahu. Umožňuje tiež dlhšie skladovanie potravín.

-

Odlepovacia hliníková koncovka na potraviny a nápoje POE 300

Keď ľudia používajú tradičné ľahko otvárateľné konce, nevyhnutne riskujú zranenie ostrými hranamimôžekoniec. Avšak,odlúpnuťviac než len vynahrádza tento nedostatok. Vďaka mäkkej textúre sa odlupovacie konzervy ľahko oddeľujú a zároveň zaisťujú bezpečnosť používateľa. Keďže sú vyrobené z bezpečných materiálov, ľudia sa nemusia obávať, či ovplyvnia požívateľnosť konzervovaných potravín.

-

Odlepovacia hliníková koncovka na potraviny a nápoje POE 305

Kuchynské roboty môžu použiť odlupovacie fólie na zlepšenie pohodlia, ochranu čerstvosti produktov a vytvorenie odlíšenia značky. Odlupovacie fólie ponúkajú rýchle a jednoduché odstránenie a pozostávajú z tenkých, flexibilných panelov tepelne pripevnených k pevnému oceľovému alebo hliníkovému krúžku. Spotrebitelia stačí uchopiť malú úchytku na veku a otvoriť balenie jednoduchým a plynulým pohybom, tieto fólie uľahčujú a zrýchľujú otváranie konzerv s potravinami.